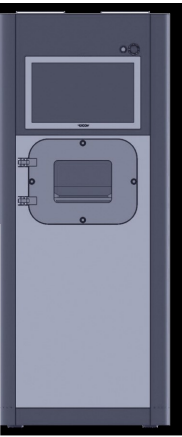

Machine profile of SAM S 250: Additive Manufacturing System for the Fast and Efficient Production of Delicate Metal Parts

Software

SAM PRINT

Building volume

ø 250 × 200 mm (ø 9.8 × 7.9) (height incl. build plate)

Laser type

Yb fibre laser; 500 W

Precision optics

F-theta lens; high- speed scanner

Scanning speed

Up to 7.0 m/s (23 ft/s)

Focus diameter

40 μm

Recommended installation space

Min. 2.5 × 3.00 × 1.00 m (8 × 10 × 3 ft)

Materials

All Printable Power

Power supply

240 - 200 V

Power consumption

Max. 1.7 kW/ average kW

Inert gas supply

4,000 hPa, 50 l/min

Inert gas consumption

For flooding: up to 600

During building: up to 2,5 I/min

Dimensions (W*D*H)

900 × 800 × 2150 mm (37 × 31 × 84 in)

Weight

760 kg

Optional Accessories

SAM laser, wet separator, blasting cabinet

While our machine shares the same spec with those of SLM solution and EOS, we offer up to 20% lower price, ensuring an internal rate of return of 20-25%

|

Options

|

EOS M 100

|

SAM S 250

|

|---|---|---|

|

Size

|

800 x 950 x 2.250 mm

|

900 × 800 × 2150 mm

|

|

Weight

|

580 kg

|

760 kg

|

|

Country

|

Germany

|

UAE

|

|

Building plate

|

100 × 95 mm

|

250 × 200 mm

|

|

Laser type

|

Yb fibre laser; 200 W

|

Yb fibre laser; 500 W

|

|

Price

|

$ 350,000

|

$ 380,000-420,000

|

Notes :

- The final product of SAM S 250 are lighter because of (1) manufacturing method, (2)materials used

- Bigger building plate widens the range of products that can be created by the machine

- 200 W is limited to medical equipment use while 500 W can be used to create components of a wider range of industries

- Scale of manufacturing also significantly differs from other products in the market

- Note that we implement Double way feeding machines which compared to one way feeding machines, are faster in manufacturing